Unlocking Business Success with Hot Melt Glue Box Sealing Machines

In the ever-evolving landscape of packaging technology, businesses must continually seek innovative solutions to enhance productivity, ensure product integrity, and reduce operational costs. At the forefront of this technological revolution are hot melt glue box sealing machines. As industry leaders like ShineBen continue to develop state-of-the-art packaging equipment, these machines have become indispensable for manufacturers striving for excellence. This comprehensive guide explores the benefits, features, and future potential of hot melt glue box sealing machines in transforming your business operations.

What is a Hot Melt Glue Box Sealing Machine?

A hot melt glue box sealing machine is an advanced piece of packaging equipment designed specifically to seal cartons, boxes, and containers efficiently using hot melt adhesive technology. Unlike traditional sealing methods such as taping or stapling, hot melt glue offers a cleaner, more secure, and faster sealing process.

This machine heats the adhesive to a liquid state, applies it precisely along the seam of the box, and solidifies quickly upon cooling, ensuring a tight and durable seal. The process significantly reduces human error and manual labor, increasing throughput and minimizing material waste.

At ShineBen, our hot melt glue box sealing machines are engineered with cutting-edge technology to cater to a wide array of industries, including e-commerce, food packaging, pharmaceuticals, and consumer goods.

Core Benefits of Using Hot Melt Glue Box Sealing Machines in Business

Implementing hot melt glue box sealing machines can catalyze significant enhancements across various facets of your business. Some of the paramount advantages include:

- Increased Efficiency: High-speed sealing capabilities allow for rapid processing of large volumes, reducing lead times and accelerating order fulfillment.

- Improved Seal Quality: Strong, uniform seals minimize the risk of product contamination, tampering, or spillage, ensuring customer satisfaction and compliance with industry standards.

- Cost Reduction: Automation reduces labor costs and minimizes material wastage associated with manual sealing methods.

- Versatility: Capable of sealing various box sizes and materials, these machines adapt seamlessly to changing business needs.

- Enhanced Safety: Modern hot melt glue box sealing machines come equipped with safety features such as automatic shutdowns and temperature controls, safeguarding operators.

- Sustainability: Using eco-friendly adhesives and reducing packaging waste aligns your business with sustainable practices, appealing to environmentally conscious consumers.

Key Features of Modern Hot Melt Glue Box Sealing Machines

The technological sophistication embedded within hot melt glue box sealing machines enables them to outperform traditional packaging methods. Essential features include:

- Precision Temperature Control: Maintains optimal adhesive temperature for consistent flow and bonding strength.

- Adjustable Sealing Speed: Allows customization based on box size, adhesive type, and production requirements.

- Automatic Glue Dispensing System: Ensures precise and uniform application of glue, preventing waste and ensuring perfect seals.

- Robust Construction: Made with corrosion-resistant materials for durability and longevity in demanding industrial environments.

- User-Friendly Interface: Touchscreen controls and intuitive programming make operation accessible even for less experienced staff.

- Energy Efficiency: Modern machines are designed to minimize power consumption without compromising performance.

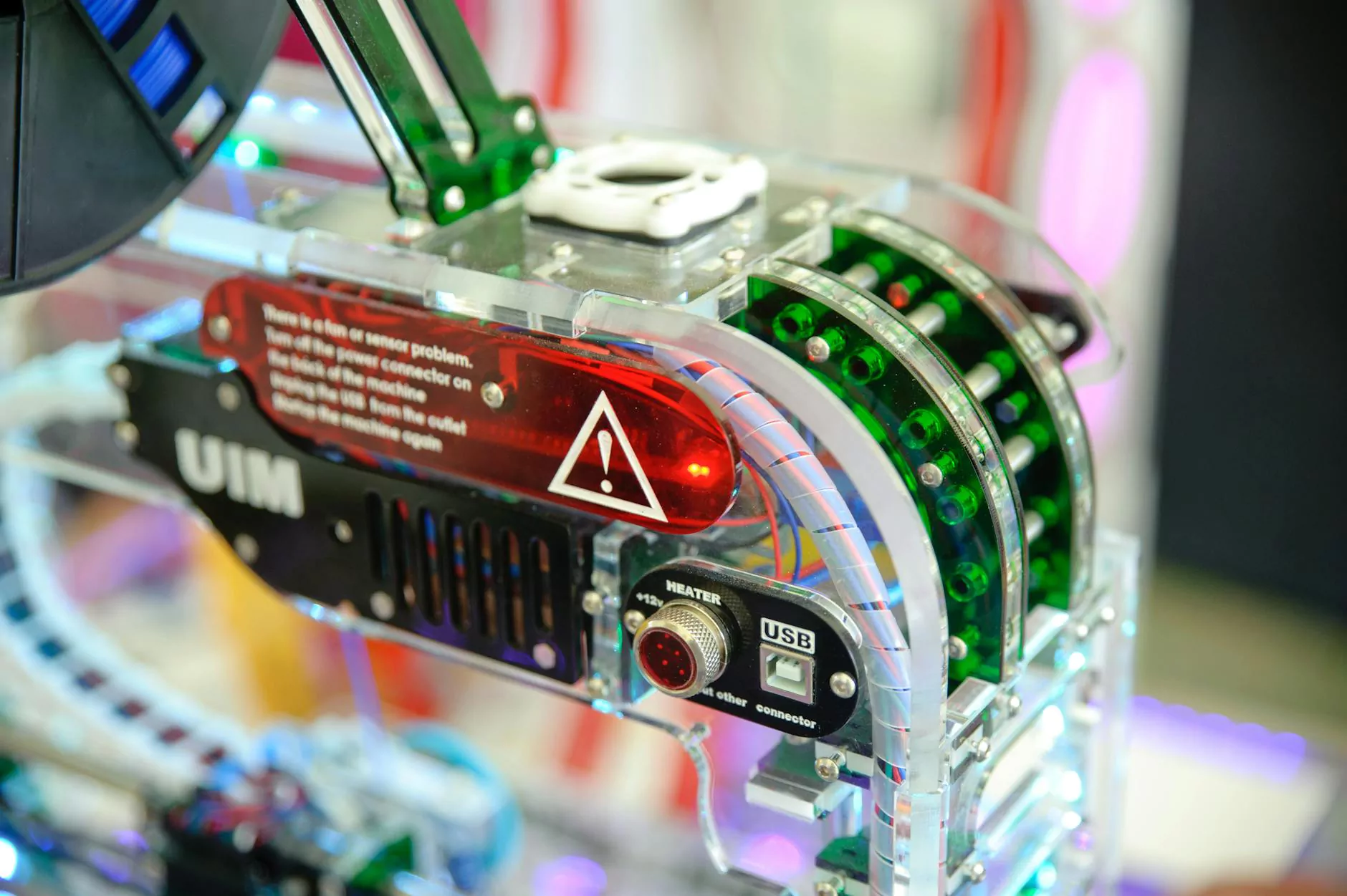

- Safety Mechanisms: Features such as emergency stop buttons, safety covers, and temperature sensors prevent accidents and machine damage.

How a Hot Melt Glue Box Sealing Machine Transforms Your Manufacturing Process

The integration of hot melt glue box sealing machines into your production line can dramatically streamline multiple processes, including:

Enhanced Sealing Consistency

Manual sealing methods are prone to inconsistencies, leading to weak seals or overuse of adhesive. Automated machines guarantee uniform application every time, resulting in high-quality seals that uphold brand reputation.

Speed and Throughput

High-speed operation can process hundreds of boxes per hour, significantly boosting output and reducing bottlenecks in packaging lines. This scalability is crucial for business growth, especially during peak seasons.

Labor Optimization

Automated sealing reduces the reliance on manual labor, freeing staff for more strategic tasks like quality control, assembly, or logistics management. This shift improves operational efficiency and reduces labor costs.

Material Savings and Waste Reduction

Precise adhesive dispensing minimizes excess glue usage, lowering material expenses. Additionally, uniform sealing extends the lifespan of packaging materials by reducing rework and returns caused by sealing failures.

The Future of Business with Innovative Packaging Technologies

The packaging industry is embracing technological advancements at an unprecedented pace. Hot melt glue box sealing machines are only one facet of a broader movement toward smarter, more sustainable, and more efficient packaging solutions.

Future developments are likely to focus on integration with Industry 4.0 systems, incorporating IoT sensors for real-time monitoring and predictive maintenance. Such innovations will further reduce downtime, optimize resource use, and enable data-driven decision-making.

Moreover, environmental considerations will drive the development of biodegradable adhesives and energy-efficient machinery, aligning business operations with global sustainability goals.

Why Choose ShineBen for Your Packaging Equipment Needs?

As a leading Packaging Equipment Manufacturer, ShineBen specializes in delivering innovative, durable, and highly customizable hot melt glue box sealing machines. Our commitment to quality, customer-centric design, and ongoing technological innovation ensures that your business stays competitive and future-ready.

Our comprehensive services include:

- Customized Solutions: Tailoring equipment to specific industry needs and box sizes.

- Technical Support and Maintenance: Ensuring optimal performance and minimal downtime.

- Training and Consultation: Helping your team operate machines safely and efficiently.

- Research and Development: Continually innovating to meet emerging market demands.

Conclusion: Elevate Your Business with State-of-the-Art Packaging Technology

In today's highly competitive marketplace, embracing advanced hot melt glue box sealing machines from a trusted manufacturer like ShineBen is not just a choice—it's a strategic imperative. These machines offer unmatched speed, reliability, and quality, positioning your business for sustainable growth and success.

Investing in cutting-edge packaging technology ensures your products are sealed with precision, safety, and efficiency, creating a positive impression with your customers and boosting your brand reputation. As industry leaders, ShineBen is dedicated to providing you with the best solutions to keep your business at the forefront of innovation.

Experience the future of packaging today—trust ShineBen’s hot melt glue box sealing machines to take your manufacturing process to new heights.